Predrilled Seat Patterns

Ever wonder how woodworkers drill those odd-angled, perfectly placed leg holes on the underside of chairs and stools and some tables?

Family Handyman

Family Handyman

The Perfect Template

Ever wonder how woodworkers drill those odd-angled, perfectly placed leg holes on the underside of chairs and stools and some tables? The respond is a custom drilling template that tin exist used over and over for dozens of identical article of furniture pieces. Information technology doesn't take long to make a drilling pattern. And once it's finished, yous simply clamp it on the seat-to-exist, drill through the holes, trace the pattern onto the stock, cutting it out and glue in the legs.

How to Brand this Blueprint

Step i: Create the guide holes

Gum and spiral together two pieces of three/4-in. MDF with i-1/4-in. screws. Set a drill printing to the desired leg angle, and drill guide holes so they come up out at the proper hole locations on the seat top with a Forstner bit sized to the corresponding holes in the seat.

Step ii: Cutting the seat shape

Cutting the shape you lot desire and clamp it to the seat stock and drill the holes (use a piece of plywood underneath to avoid tear-out). Then trace around the pattern and saw out the seat.

Step three: Drill holes into the seat

Use a Irwin Speedbor bit to drill the seat holes; the guide hole will go on it perfectly angled while you're drilling. These Irwin auger-style bits are very aggressive, so set up the drill at a slow speed and practice on a chip board so you don't wreck your artwork. Check out these must-have drill attachments also!

Click here to buy a 1-in. Irwin Speedbor bit from Amazon.

13 Dirt-Simple Woodworking Jigs Y'all Need

Family Handyman

Family Handyman

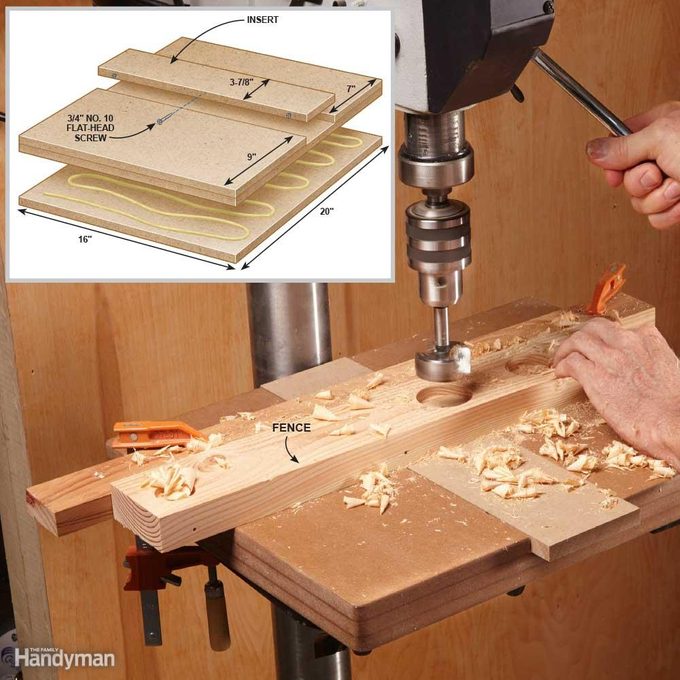

Drill Press Tabular array

Many drill printing tables are also small for woodworking because they were designed for metalworking. Likewise, standard drill press tables don't take a fence or an insert to back upward holes drilled all the mode through a piece of woods. This jig solves these problems! Make the table from three layers of 1/2-in. medium-density fiberboard glued together. It's fastened to the machine's table from underneath with four lag screws. The table'south top layer is composed of three pieces. The outer pieces are glued to the table, while the center slice—the insert—is loose. The insert is 1/8 in. narrower than the gap between the two outer pieces. Install iii flat-head screws in the side of the insert and adjusted them and so the insert fits snug in the gap. When yous demand a fresh surface to drill into, slide the insert in or out, flip it around or flip it over. Likewise, brand a few actress inserts and then yous tin toss one away when it starts looking like Swiss cheese. The fence is just a plain board clamped to the table.

Jig for Routing Dadoes

When building a chiffonier, dadoes are often used to ensure that shelves and partitions are spaced correctly. To brand a potent joint, the width of the dadoes must exactly match the thickness of the plywood. That can be a claiming because few pieces of plywood are precisely 3/four in. thick. They're normally 1/32 in. or so less than the "nominal" thickness. This jig will rout perfect-fitting dadoes for any piece of 3/iv-in. plywood regardless of its actual thickness. Use a special elevation-bearing trim router flake with the jig. The bit is 1/two in. wide, ane/2 in. long and has a bearing mounted above the cutter. The begetting is flush with the chip's cutting edges. This routing jig has 2 long, parallel guides made from i/ii-in. MDF. When you rout a dado, ride the bearing along i guide, then brand a second, return pass and ride the begetting forth the second guide. This way, the space betwixt the guides determines the width of the dado. Setting upwardly the guides is easy. I guide is stock-still to the jig'due south 3/iv-in. cross members; the other is loose and adaptable. Have ii small pieces of the plywood and place them against the fixed guide. And so slide the adjustable guide against the pieces and clench the guide to the cantankerous members. Washed!

Find out how to use a pocket screw jig, besides, in the video below.

Family unit Handyman

Family unit Handyman

Sacrificial Table Saw Fence

When you have to arrange the table saw's fence so it sits right side by side to the bract, put a "sacrificial" argue on the saw. Using a sacrificial contend helps yous avert accidentally cutting into the real fence, which would be really bad news. This sacrificial contend is made of four thicknesses of 1/ii-in. MDF glued together. (Threequarter- inch plywood would work but equally well.) Cut the middle pieces into thirds in society to create holes for clamping. The holes ensure that the clench's heads won't get in the style when you lot're making a cut. The beauty of this system is that yous tin use all sides of the fence until it wears out—merely information technology'due south easy to make another!

Family Handyman

Family Handyman

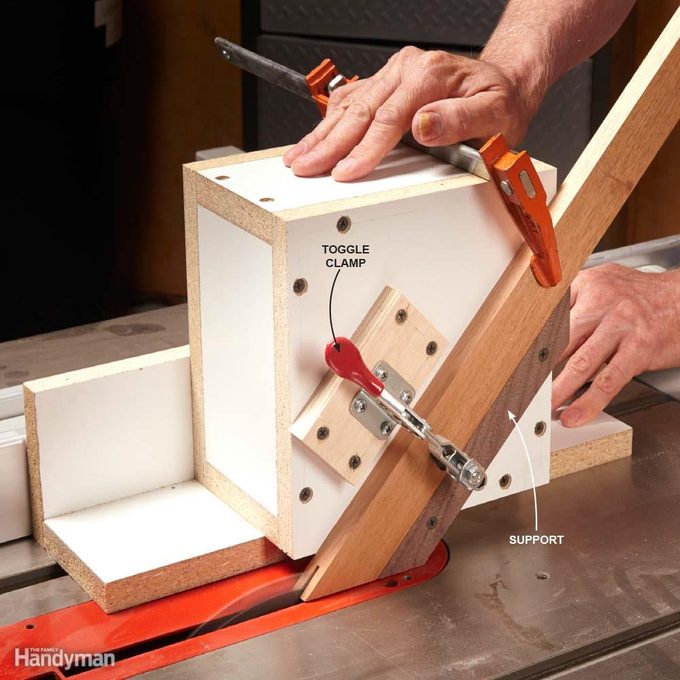

Table Saw Guide Box

When you have to stand up boards on cease to machine them on a tabular array saw, pull out this unproblematic box. It steadies the wood and so you go a straight cutting. The box is made of melamine and measures 8 in. square and 5-one/ii in. deep. It'south screwed to two optional runners that are 12 in. long. Here, we show cutting slots into the ends of each office of a film frame and then the parts can be joined with spline (sparse pieces of solid wood). You couldn't do this using the tabular array saw'due south argue lone because the debate doesn't offer enough support—information technology'southward not tall enough. Using this box, you lot're sure to get an admittedly straight cut. The picture frame piece is supported by a block that's screwed to the box. If you need to support pieces at xc degrees—for cutting tenons, for case—but remove the 45-degree support and screw on some other. To ensure a straight cut, clamp the workpiece to the box. Use a toggle clamp to concur the frame's lower end because it'southward hard to get a regular clamp down there. The tabular array saw's debate gets in the way. Y'all tin buy a toggle clamp at a woodworking store or online.

Family Handyman

Family Handyman

No-Wiggle Tabular array Saw Crosscuts

If your miter gauge's bar wiggles in the saw'south miter slot, you'll have a hard time getting an absolutely straight crosscut. Hither's a way to fix that: Employ ii miter gauges connected by a debate. An extra miter gauge isn't very expensive, but you can cutting the cost to zero by making one yourself. Gum two pieces of Baltic birch plywood together to form an L-shape body, then carefully cut a bar to fit snugly into your saw's miter slot. Apply a piece of maple to make the bar, or 1/four-in. tempered hardboard is another skilful option. Glue the bar to the body using spring clamps, so you can easily adjust the bar to be exactly 90 degrees to the body before the gum sets. Install screws later. Yous probably won't be able to utilize your saw's guard with this setup, and so it'due south a good idea to add a plastic shield to the fence. The shield will remind yous non to put your fingers likewise close to the bract and will keep the sawdust out of your eyes.

Family unit Handyman

Family unit Handyman

Heave Your Vise's Belongings Ability

When you clamp a board using simply one side of your vise, have you noticed that the lath frequently slips or rotates if you push button down on it? That'due south because the vise'south jaws don't stay parallel when the vise is tightened. Your board is getting pinched only along one border. Even the all-time vises "rack" similar this. Fixing the problem is quite simple. You only need to identify a spacer on the reverse side of the vise. The spacer should be the aforementioned thickness as your workpiece—a bit offcut works well. Drive a spiral into ane end of the spacer or pinch it with a bound clamp then you don't have to hold on to the spacer while tightening the vise.

Family Handyman

Family Handyman

Extra-Big Sander Table

Benchtop disc sanders come with small tables. If you demand a larger table, make a new one and clench it to the original table. At get-go yous might think you'll add the extra-large table only when yous demand it, merely one time you put it on, yous might never take it off! This jig is far fancier than it has to be—a evidently slice of melamine would have sufficed.

Family unit Handyman

Family unit Handyman

Squaring Blocks

A cabinet that's out of foursquare is like a house built on a foundation that's not level. Expert luck getting doors to hang right! When you mucilage and clench up a instance, employ a couple of "squaring blocks" to make sure the case has 90-caste corners. Clamp the blocks to the case before putting the final squeeze on the instance's clamps. This type of squaring block is very piece of cake to brand. First, cut a piece of plywood about viii in. square. (Make certain the within corner is truly square by testing information technology with a combination foursquare.) Next, spiral two 3/iv-in. 10 2-3/four-in. x 7-in. lips to adjacent sides of the block for clamping. Leave a gap at the inside corner of the cake so you can remove glue that squeezes out of the joint.

Family Handyman

Family Handyman

Three-Layer Hole Drilling Spacer

You lot may have seen this trick before—using a piece of pegboard to drill evenly spaced holes for shelf pins. Merely here'due south another take on information technology: Brand the jig from three layers of pegboard. A thick jig has a couple of advantages. First, the holes won't wear out every bit fast (holes in a single layer of pegboard tend to go oval rapidly). Second, the boosted thickness will help go along your drill perpendicular to the panel. When using the jig, record over the holes you don't demand so you lot don't make a dumb error. Too, slide a wood cake onto the drill bit to limit the hole depth. And then, how practise you keep the holes aligned when gluing the pieces together? Information technology'southward really quite simple. Insert a couple of 1/iv-in. automobile bolts through reverse ends of the glue-up, so add washers and basics. Tightening the nuts volition force the pieces into alignment and keep them at that place. Trim the edges of the jig after the glue dries.

Family Handyman

Family Handyman

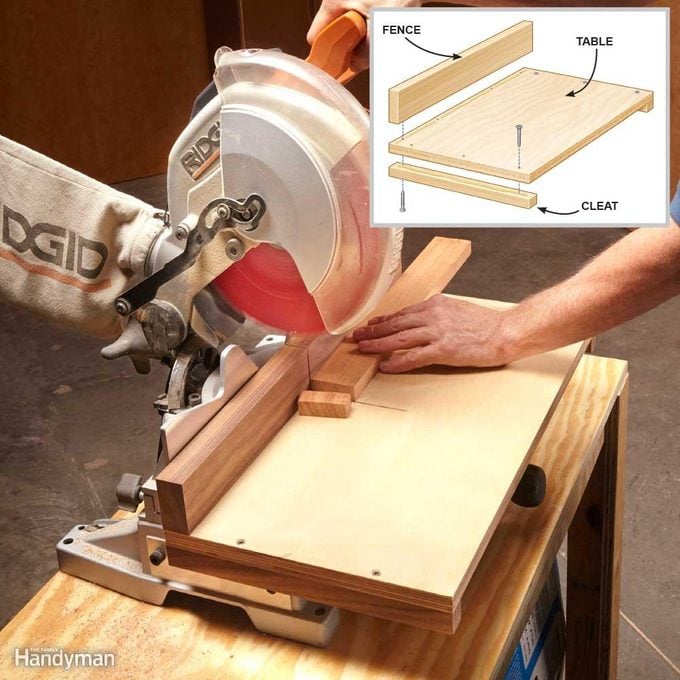

Accurate Miter Saw Cuts

Clamp this small Baltic birch table to your miter saw when y'all want to cut a few short pieces to an exact length. The slot in the table's contend shows you lot precisely where the bract will cut—just mark the piece with a pencil and line up the mark with the slot. The slot has "nix clearance," meaning there'due south no gap on either side of the blade. The slot in the tabular array is zero clearance besides. Zero-clearance slots reduce tear-out to an absolute minimum, eliminating splintered edges. When this table was made, the contend was one long slice of wood. Cleats were screwed to the tabular array's ends to lock the table in place. And so the saw was lowered to cutting the slot in the fence. Note that the table must exist wider than the saw'southward turntable—the uncut portion of the table is what holds it together!

Family Handyman

Family Handyman

Adjustable Fence

Add together an adjustable fence to your drill press to get in a lot handier for woodworking projects! A fence is especially useful for drilling rows of precisely placed holes. Also, irksome holes in a small workpiece is a snap—only clamp the piece to the fence at any angle and drill the hole. You lot won't struggle with holding small pieces in place while you drill. (That's besides dangerous!) 1. Attach a two-ft. x 1-ft. scrap of plywood or particleboard to the drill press table with countersunk 1/four-in. apartment head machine screws, fender washers and basics. (Run the screws through the slots in the metal table. The fender washers volition span the slots.) 2. Create the fence from a 2 ft. x 4-in. 10 1-in. board bolted to a 2-ft. piece of 3-in. x one/8-in. aluminum angle iron ($10 at a home center for a 4-ft. length). Once more, countersink the holes in the lath before bolting the board to the angle iron.

Family Handyman

Family Handyman

Vertical Drilling Jig

If you've ever tried to drill a perfectly directly and centered deep hole in the end of a board, you know that it's almost impossible with a handheld drill. But add a drill press and a jig and the task becomes very achievable. Make this jig from two eight-in. 10 12-in. pieces of iii/4-in. plywood or medium-density fiberboard (MDF). Just spiral the pieces together to form a "T" and reinforce the jig with a couple of triangles. To use the jig, clench it to the drill press table and the workpiece to the jig. Draw an "Ten" across the corners to find the exact heart of the piece. Y'all'll take to adjust the height of the tabular array and pin it until you lot line everything up, but after that, drilling a straight, centered hole is a cinch. This trick will work for rectangular or foursquare boards. Try these incredible drill press jigs as well!

Family Handyman

Family Handyman

Cut Narrow Strips with a Sliding Jig

To make a serial of identical narrow strips for shelf edging, you don't need to remove the blade guard or motion the fence for every cut. Just attach a short strip of wood slightly thinner than the width of the rip cut to the end of a 4-ft. 1×half dozen. Then hold the board confronting it and push the jig through. The jig keeps your hands well away from the blade, and you lot tin can rip every bit many pieces as you need without ever moving the argue. To make the jig, attach a 5-in.-long strip of woods, ane/16 in. narrower than the width of the desired rip, to the finish of a 1×6 as shown. Basically you're creating a horizontal push stick. Add a handle nigh the end of the jig to give yourself better control as you run the jig through the saw.

Source: https://www.familyhandyman.com/article/predrilled-seat-patterns/

Posting Komentar untuk "Predrilled Seat Patterns"